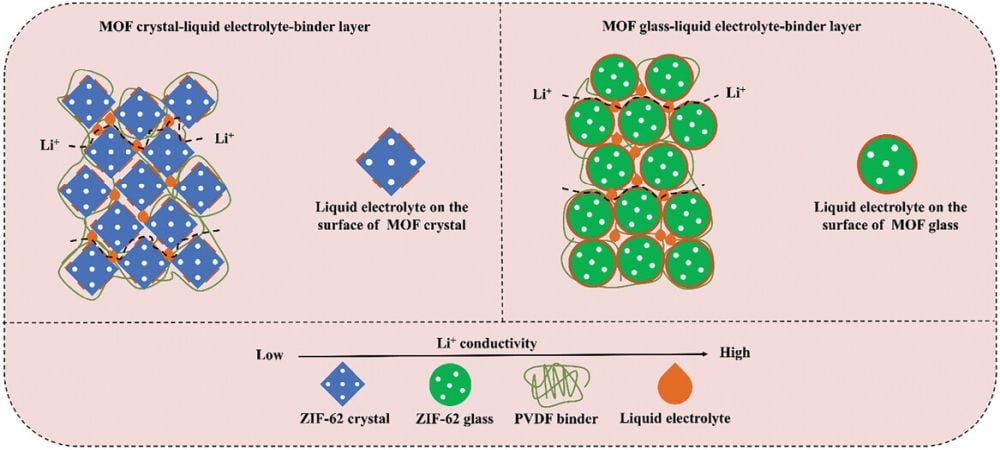

[Image above] Schematic of the proposed mechanisms of lithium-ion diffusion in ZIF-62 crystal and glass layers. Lithium transport through the internal pores of ZIF-62 glass is faster owing to ZIF glasses possessing both a disordered structure at all length scales and a depolymerized network. Note: the white spots are the internal pores of the ZIF-62 glass/crystal. Credit: Ding et al., Advanced Materials (CC BY 4.0)

The rapid growth in solar and wind energy is often the focus of clean energy discussions, but the massive expansion of batteries is the key technology helping enable this transition.

Batteries store energy for later use, and this capability is critical for making the most of renewable energy sources that are not consistently available. Since 2016, the total lithium-ion battery market grew by 10 times, with the energy sector now accounting for more than 90% of annual lithium-ion battery demand, according to the International Energy Agency’s special report on “Batteries and secure energy transitions.”

Despite this progress, global energy storage capacity needs to increase sixfold by 2030 to keep the world on track for its energy and climate goals, according to the report. Batteries are expected to account for 90% of the increase, while pumped hydropower will comprise most of the rest.

Rather than simply producing more lithium-ion batteries, the current mainstay of the energy storage market, researchers are hoping to meet this demand through alternative battery technologies that are safer and more efficient. For example, lithium-metal batteries, which use electroplated lithium metal as the anode material rather than graphite, can store twice the energy of a lithium-ion battery in the same amount of space.

However, scale-up of lithium-metal batteries is hindered by the battery’s propensity for lithium dendrite formation. Lithium dendrites are spiky, treelike microstructures that form when extra lithium ions accumulate on the anode surface. The lithium dendrite can react with the electrolyte, causing it to decompose and triggering the loss of active lithium inside the battery, thereby reducing the battery’s storage capacity.

Lithium dendrites occur in lithium-ion batteries, but their occurrence in lithium-metal batteries is exacerbated by the lack of spatial control over lithium nucleation on the lithium metal anode. So, suppressing lithium dendrite formation is vital to making lithium-metal batteries a reliable battery technology.

The use of solid-state rather than liquid electrolytes is a favored approach to suppressing lithium dendrite formation. Solid-state electrolytes typically have higher mechanical strength compared to liquid electrolytes, which helps prevent dendrites from penetrating through the electrolyte. Plus, some solid-state electrolytes have higher ionic conductivities than liquid electrolytes, which allows efficient lithium-ion transport and thus helps promote more uniform lithium deposition, reducing the likelihood of dendrite formation.

Glass is emerging as a possible material for solid-state electrolytes. As explained in the cover story of the May 2023 Bulletin, glass typically offers lower processing temperatures and more tunable chemistries than polycrystalline ceramics, which are also being investigated for solid-state electrolytes. However, reconciling the low conductivity of oxides and the high reactivity of sulfides to form glasses that are highly conductive and stable against alkali metals, such as sodium or lithium, is a challenge.

Rather than using glass as the entire electrolyte, researchers from Aalborg University in Denmark, including ACerS member Morten M. Smedskjaer, investigated the possibility of placing a glass layer between the lithium metal anode and liquid electrolyte.

The glass used in this study is based on metal–organic frameworks (MOFs). MOFs are a relatively new class of materials comprised of inorganic nodes joined by organic linkers. Despite their comparative novelty, researchers have recorded more than 80,000 distinct crystal structures for MOFs in the literature.

In their crystalline state, MOFs typically display high porosity. In the context of batteries, this characteristic is beneficial for controlling the transfer of large-sized anions within the electrolyte and anode. Consequently, researchers can attain uniform lithium-ion flux and stable lithium plating and stripping.

This benefit is offset, though, by the internal anisotropy of crystalline MOF particles and the different crystal facets exposed on the particle surfaces. These factors limit the potential of crystalline MOFs to regulate the ion transport kinetics.

Fortunately, several MOFs can be formed as glasses, including the important family of zeolitic imidazolate frameworks (ZIFs). These MOF glasses retain the high porosity, which many traditional glasses lack, while avoiding the drawbacks of the crystalline MOF phase.

In the recent open-access study, the researchers compared the performance of glassy ZIF-62 to crystalline ZIF-62. Specifically, they looked at the rate of lithium-ion diffusion and the smoothness of the diffusion channels both in the monolithic MOF glass interior and the interface between the glass particle and liquid electrolyte.

First, they used ab initio and classical molecular dynamics simulations to compare the two MOFs. The simulations confirmed the hypothesis that the glass layer supports superior performance by enhancing interfacial interactions between the anode and liquid electrolyte, thus increasing lithium conductivity.

Then, they coated a lithium-metal anode with the ZIF-62 glass layer. The coated anode successfully operated for more than 300 hours at 1 mA cm−2 in symmetric batteries.

“Thus, the strategy of utilizing a MOF glass layer enables the development of high-performance dendrite-free [lithium-metal anodes],” the researchers write.

The researchers now plan to explore the use of conductive 2D materials to help regulate the electronic conductivity and mechanical properties of the MOF glass layer.

The open-access paper, published in Advanced Materials, is “High-performance dendrite-free lithium-metal anode based on metal–organic framework glass” (DOI: 10.1002/adma.202400652).