Additive manufacturing offers a potentially easier way to fabricate cemented carbide parts. In a recent paper, researchers from Global Tungsten & Powders Corp. in Pennsylvania explored whether ensuring a uniform grain size in the 3D-printed part will improve its properties.

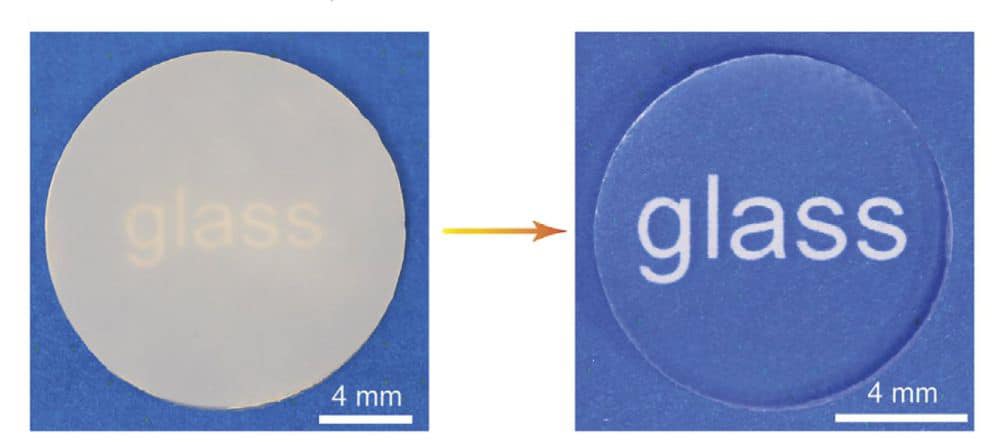

Read MoreIn 2020, researchers led by the University of Maryland developed an ultrafast high-temperature sintering method to achieve rapid, pressureless sintering of ceramics. Now, they and colleagues from Alfred University and the University of California, San Diego used this method to fabricate high-quality silica glass.

Read MoreDigital light processing is one of the most promising additive manufacturing technologies for preparing ceramic scaffolds with complicated fine features. Three recent studies by several groups in China explore the use of this technique to fabricate bioceramic scaffolds for medical applications.

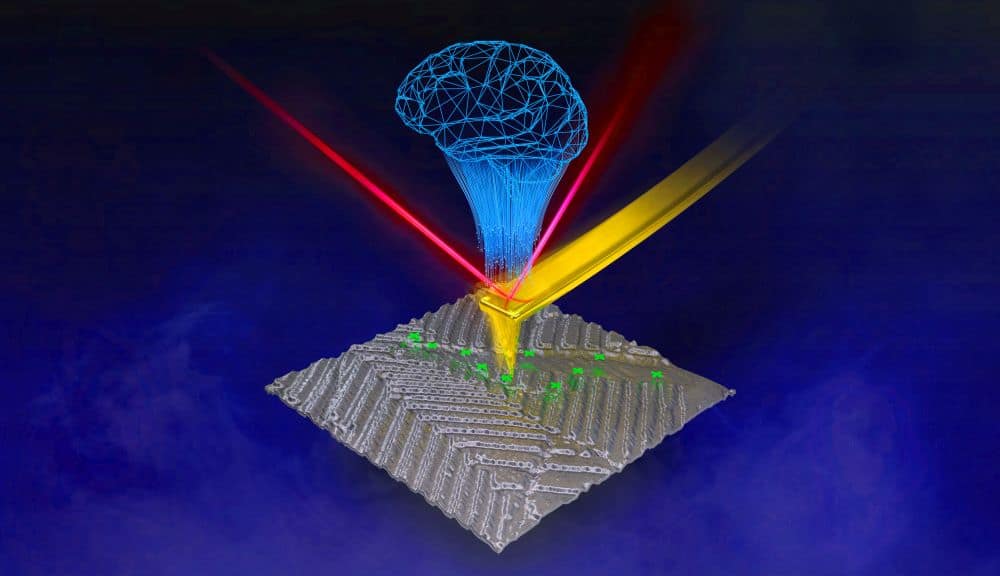

Read MoreStoring data generated by sophisticated microscopy instruments is quite easy, but accessing, interpreting, and acting on the terabytes of data is challenging. Two recent papers offer interesting approaches to interacting with electron microscopes and the data they produce.

Read MoreMining rare earth ores is only the first step in securing the rare earths supply chain. These ores must undergo refining processes, and China controls nearly all of the world’s rare earth processing facilities. Two U.S. mining companies, MP Materials and USA Rare Earth, plan to open domestic rare earth processing facilities within the next year.

Read MoreFlash-sintering of ceramics can lead to microstructural heterogeneity, which can negatively impact the material’s performance. Researchers in Brazil demonstrated that forming method can influence the final microstructure of flash-sintered ceramics.

Read MoreOxide–oxide ceramic matrix composites have desirable properties for use in engine components, but conventional processing techniques usually require high temperatures and pressures, which damage the oxide fiber. Researchers in India developed a one-step process for synthesizing mullite precursors that could lower sintering temperature.

Read MoreWith the rising use of fuels with reduced sulfur content, novel coatings are needed to protect engine components from increased wear. Researchers from Brazil and Chile investigated the potential of a hybrid deposition technique to deposit nanostructured ceramic multilayers on piston rings.

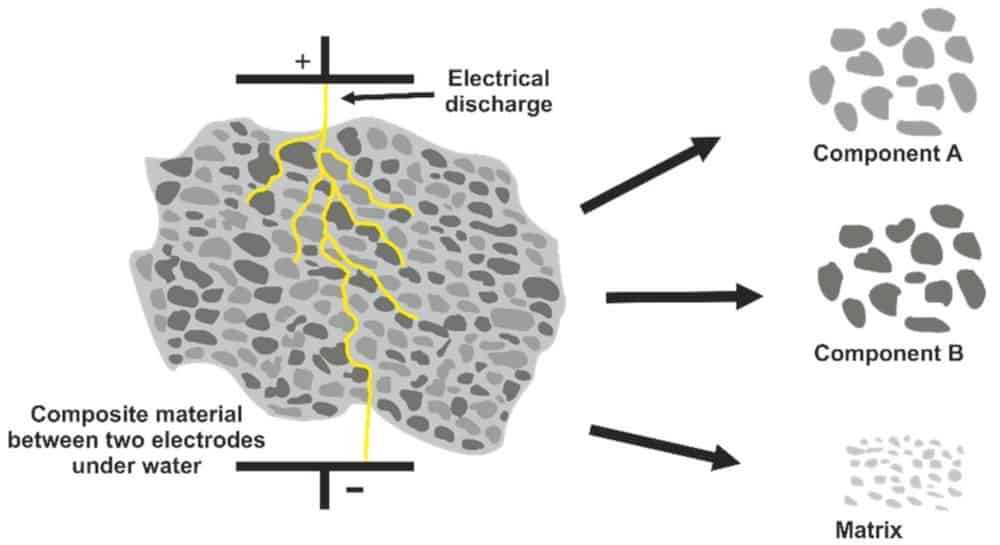

Read MoreRecycling and reusing waste materials is one approach the refractories industry is pursuing to improve sustainability. Researchers at the Fraunhofer Institute for Building Physics have explored the potential of electrodynamic fragmentation to recycle composites, and their recent study looks specifically at the potential of this technique applied to refractory materials.

Read More